- What information can you assume your CM will handle?

- Reflow profile considerations

- Solder specifications and BGAs

- Parts washing requirements

- Panelizing PCBs: Why it's best left to your CM

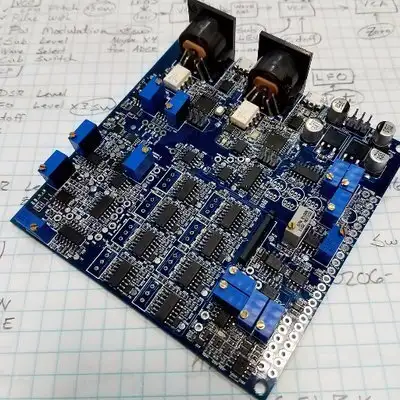

- Personal Project Updates: PropFan controller

- Switching to a SamD21 MCU for the PropFan

- Using the LT8672 for circuit protection

- Details on the Crystal Fontz CFA533-TFH-KC display

- Implementing I2C to differential pair conversion with PCA9615

- Using Ethernet to connect the display and PWM controller

- Exploring current sensing for fan control

- Potential features and future expansions for the PropFan

- Challenges with GPS speed control and automotive applications

- Importance of proper connector and enclosure selection for automotive electronics

- Top 10 Episodes for Electronic Engineers

- Comprehensive Power Supply System Designs for Harsh Automotive Environments

- What are your thoughts on allowing your CM to handle PCB panelization?

- Have you ever encountered unique reflow profile requirements for specific components in your designs?

- What features would you like to see in an open-source automotive fan controller?

Creators and Guests

What is Circuit Break - A MacroFab Podcast?

Dive into the electrifying world of electrical engineering with Circuit Break, a MacroFab podcast hosted by Parker Dillmann and Stephen Kraig. This dynamic duo, armed with practical experience and a palpable passion for tech, explores the latest innovations, industry news, and practical challenges in the field. From DIY project hurdles to deep dives with industry experts, Parker and Stephen's real-world insights provide an engaging learning experience that bridges theory and practice for engineers at any stage of their career.

Whether you're a student eager to grasp what the job market seeks, or an engineer keen to stay ahead in the fast-paced tech world, Circuit Break is your go-to. The hosts, alongside a vibrant community of engineers, makers, and leaders, dissect product evolutions, demystify the journey of tech from lab to market, and reverse engineer the processes behind groundbreaking advancements. Their candid discussions not only enlighten but also inspire listeners to explore the limitless possibilities within electrical engineering.

Presented by MacroFab, a leader in electronics manufacturing services, Circuit Break connects listeners directly to the forefront of PCB design, assembly, and innovation. MacroFab's platform exemplifies the seamless integration of design and manufacturing, catering to a broad audience from hobbyists to professionals.

About the hosts: Parker, an expert in Embedded System Design and DSP, and Stephen, an aficionado of audio electronics and brewing tech, bring a wealth of knowledge and a unique perspective to the show. Their backgrounds in engineering and hands-on projects make each episode a blend of expertise, enthusiasm, and practical advice.

Join the conversation and community at our online engineering forum, where we delve deeper into each episode's content, gather your feedback, and explore the topics you're curious about. Subscribe to Circuit Break on your favorite podcast platform and become part of our journey through the fascinating world of electrical engineering.

Welcome to circuit break from Macrofab, a weekly show about all things engineering, DIY projects, manufacturing, industry news, and mind reading contract manufacturers. We're your hosts, electrical engineers, Parker Dillmann. And Steven Kraig. This is episode 438. It's been a while since we have not had a guest.

Stephen Kraig:And we have a bunch of guests coming up they're actually gonna be really cool.

Parker Dillmann:Yeah. Yeah. So this has got this is like a little break for us.

Stephen Kraig:Yeah. A little breather.

Parker Dillmann:Yeah. Yeah. Speaking of breathers if you all have time you listeners, I just posted a article called top 10 episodes for electrical engineers for the circuit break podcast. Go check that out. We have this is kinda like another, like, introduction, but for, like, engineers to the podcast.

Parker Dillmann:So we have, like, the episode with Bill Heard. We have the Chips Act. We have probably 1 of my favorite episodes the, mislabeled label mislabeled levels of hell where Steven told his story about

Stephen Kraig:buying wrong hardware at your local hardware store because people put it

Parker Dillmann:in a wrong bin. Yeah. Yeah. We have product of many imaginations. That's when we had Misha and, Chris Church on, that's the CEO and the other cofounder of MacroFab on the podcast to talk about supply chain complexities.

Parker Dillmann:That was right around like the mid I think it was like midway 2020 we did that episode. Then we have the idea fab does this podcast change the world which is I think my I say my all these are like my favorite. I love these episodes.

Stephen Kraig:That's why they're on the top 10.

Parker Dillmann:That's why they're on top 10 list. Yeah. It's hard. It's hard. I don't think I could pick 1 episode.

Stephen Kraig:Gosh. Well, I mean okay. So out of this many episodes, yeah, it's pretty hard.

Parker Dillmann:Yeah. But, yeah, the idea of that podcast if if you're a new listener, that's a collaboration between the Idea Tank podcast and and and us, the circuit break podcast, where we have Scott and Eric, come on the podcast and then they pitch us like reasonable ideas, Kinda like Shark Tank and then we pitch, like, stupid ideas.

Stephen Kraig:Just ridiculous ideas.

Parker Dillmann:That that was where Steven came up with the College of Average Joe's. Or above average Joe's. Yep.

Stephen Kraig:Yep. Yep.

Parker Dillmann:Yeah. And then we have rogue Gerber's with Jerry McDaniel who's our director of customer care. That's a really good episode that talks about kind of like how customer service works, but not just that mac fab just like in general. It's kind of cool episode. This is an old old episode your toaster is toast.

Parker Dillmann:When when did that come out say it's old it's only 335 it's only a 100 episodes ago that episode feels like another lifetime ago.

Stephen Kraig:You know, okay. So that 1 reminded me of an episode way back when when we were talking about the the toaster controller IC that was dedicated that has the bagel pin on it. And I I honestly thought that's what you were going with.

Parker Dillmann:No. Actually, the bagel pin didn't make this list. That did not. Wow. No.

Parker Dillmann:Then we have HyperSize part packages. That's a really cool episode where we talked about like different, like it was it's more of, like, not actually the footprints, but, like, the part packaging identification, like, markings and that kind of stuff. Mhmm. And then datasheet lore, which probably came up with our best idea ever that we never did.

Stephen Kraig:Okay. Wait. Wait. I'm never did is a strong term word. We haven't done yet.

Stephen Kraig:We haven't done that. Be because because I still think this is a fantastic idea, and and if I were able to do this as a full time job and, like, actually do it correctly, III think that this would I I would do it in a heartbeat.

Parker Dillmann:Yeah. But this but

Stephen Kraig:this episode was all about how a a system for determining how to pick the right part for your design.

Parker Dillmann:And it's funny that is actually is your day job almost now.

Stephen Kraig:You you actually, what I think is funny is is somehow it just kinda played, like, my career played that way. Because we had this discussion, and now I I you're right. I basically do that. Well, actually, I shouldn't say that. It's not that I picked the right part.

Stephen Kraig:I just tell people that they picked the wrong 1. That's what my job is nowadays. Actually, a little short side story. So so we got a new intern and every week, there is, on on 1 day a week, there is, like, an intern day where for 1 hour, somebody on the team gets to go and talk to the intern about what they do. And today was my my day.

Stephen Kraig:So I got to I got to tell the intern what all I do. And and what was funny was I had to actually sit and think beforehand. I was, like, what do I do? Like, of course, I know what I do, but, like, if I have to summarize it to somebody, what what do I do? And in a lot of ways, I I get to tell people that they're picking incorrect parts a little bit more than I get to tell people that they're correct, you know, choosing correct parts.

Stephen Kraig:So but, yeah, that that that that episode was fun and I don't think that idea is is fully dead because it's just it's too good.

Parker Dillmann:I'm surprised that no one's no 1 took that idea and made it. There was some movement with it, but this is early on in the the slack channel before we had that the the, form at forum.macrev.com. You should go check that out. Join our community. If you have a macro account, you already have an account there.

Parker Dillmann:You just log in. It just works. You don't need an account.

Stephen Kraig:And and I've had some people reach out to me actually about this idea, and and, you know, we we had some conversations about it and how to make it a reality. And I and the the the the difficulty there was just figuring out, like, how how do you give it legs? How do you actually make this work? And and I struggled a bit with with the the basis of, like, just really like, the beginnings of it because because I know what the end result kind of looks like, but getting from a to b was just very difficult on that. And just for the all of those who are probably lost right now, this this idea was just creating a system that that basically is how do you pick a and then choose whatever part category you talk about.

Stephen Kraig:How do you pick a resistor? And then really, like, just guiding an engineer through all the intricacies and details, maybe not all of them, but the the intricacies and details of picking that part. And how do you avoid all the traps, and how do you avoid all the the difficulties, and how do you go on to your favorite vendor, pick any of them, and laser beam narrow down to the exact part you need, move on to the next 1.

Parker Dillmann:Yeah. It's kinda like a choose your own adventure for a part where, like, you go, okay, I need a resistor for your example. Mhmm. And then it'll be like, okay, you want a resistor, and then it might be like and then I'll just ask you like a question next, like, what is at this list the most important thing that you care about this resistor? Yeah.

Parker Dillmann:And it will show, like, all the important features, so, like, the resistance, of course, the power rating, size, and then you can also go in through, like, temperature code, like you can list all these properties and and specifications that meet, like, make a resistor. Mhmm. But you would have that for everything. So, like, a a BJT transistor. So because you can kind of do this through like Digikey and Mauser through their sorting algorithm thing, but this is would be more of a also like it would tell you stuff like these are the things that matter the most about a resistor.

Stephen Kraig:Well or or or like you you you see a category filled with information you have no idea what any of the things are. It could help guide you and tell you, oh, this means this and this is this other thing, and you can easily read it and go like, oh, I really care about that or I don't care at all about this, but it at least equips you with the knowledge and the information of what's being presented to you. Mhmm. In fact, it's funny. In in in my, discussion with with the Internet work today, I asked them, you know, okay.

Stephen Kraig:So you you're in college, say you're going to get a capacitor. What you know, in college, what do they teach you about? And he goes, the value and maybe the size of the package. And I was like, great. That's fantastic.

Stephen Kraig:That's exactly what they teach you in college. And I was like, what about all the other parameters? Like like, all of the other ones, we have to care about those now. And and by care about them, we have to maybe maybe 50% of them, we actually don't care about them, but we have to care enough to ask the question, do we care about whatever that parameter is. Right?

Stephen Kraig:And and, I would say telling him, like, a large portion of my job is going through all of those parameters and being, like, this is the ones we care about, these are the ones we don't. And, and I think this how to pick apart idea would basically do that exact same job. But but but really, really 0 in on all of the parameters that you don't normally see, you know, or you don't normally know you need to care about or a lot of traps that screw us up when when picking parts.

Parker Dillmann:Mhmm. And then that was episode that was the 9th episode on that list. Right. Episode 10, on that list is, chicken and tea leaves. Al's simulation recipe.

Parker Dillmann:This is Al Williams. I don't remember I don't think this is the his first episode when he was on the podcast, but this is episode Al, Al Williams came on the podcast to talk about FPGA simulation. So I'm just like writing Verilog or whatever, but it's actually like the simulation part of it. So it's a really cool episode.

Stephen Kraig:I've always enjoyed Al. He's he's been a really fun guest. We need to get him back on again.

Parker Dillmann:You wanna shoot him an email?

Stephen Kraig:Yeah. While we're recording. Yeah. Okay. So let's, let's go ahead and move into, 1 of our topics here.

Stephen Kraig:So so 1 of the things we were actually discussing at work today, and I thought it would be interesting to talk about because I no longer work at a contract manufacturer, but Parker still works at, Macrofab. It'd be really fun to talk about the information that you can assume that your Centimeters handles for you. And and it's funny because we were having a conversation at work about this exact topic, and I had a little bit of a different perspective than a lot of the other people at work, especially from our quality department. Our quality department, you know, bless their heart. They're they're fantastic, but I think they have a lot of skepticism about other people outside of their their their walls.

Stephen Kraig:They basically trust no 1, and that's kind of what quality is supposed to do.

Parker Dillmann:That's their job.

Stephen Kraig:That's their job. They don't trust anyone. So so the 1 of the things we were talking about is, your your Centimeters, is it better for you to assume that your Centimeters can handle the reflow profile of their ovens, or is it better for you to dictate to your Centimeters, here's what I need you to do with your reflow profile? So in other words, this this came up because we were talking about, parts with bald, leads, like BGAs, things like that, or any of the packages that have odd shaped pads underneath, they can have unique solder as the balls. The balls aren't always the exact same solder or the exact same flux that that your Centimeters uses and they can have a slightly different reflow profile.

Stephen Kraig:So the idea is should you rely on your Centimeters to investigate every single part and make sure that the reflow profile is correct for it, or should you be trying to present that information to your Centimeters? And I'm curious to know you what what your thoughts are on that, Parker.

Parker Dillmann:I have never seen a customer supply a reflow profile for us. Okay. But I what I do is when I I'm designing stuff, and I noticed that there's a weird thing like that, like because some manufacture like, I've never seen, like, a BGA actually specify anything like that, but I've seen connectors that are surface mount connectors that have, like, a solder slug that's, like, on the lead, and it's, like, it's, like, extra solder in the connector. Mhmm. I've seen those parts have very specific, like, pace and and flux requirements basically for the the component, And if I was designing something, install that, I would make sure that went along with my data package.

Parker Dillmann:Like mice, I would make sure my Centimeters knew that. MacFab has a feature for that. It's the, the the, there's a part where you can have you can see all of your components on your board and you can click the part and you can add a part note so you can get

Stephen Kraig:this kind of Hey, this one's special.

Parker Dillmann:Yeah. This one's got a weird thing on it.

Stephen Kraig:Yeah. Yeah. Yeah. It's got solder slugs. Okay.

Stephen Kraig:So I'll give you a bit of an example. I've ran into a part that from the manufacturer, the part the the the solder on the pads are 95 5 lead tin. So it's 95% lead, 5% tin. That's a fairly exotic solder. And and so the metallurgy that actually is required to solder that to the board requires a fairly unique reflow profile.

Stephen Kraig:So so at the you know, in in general, there's 2 kinds of reflow profiles. There's just leaded and non leaded, and I don't wanna say just, but they they fit into those 2 categories. And then within those categories, there's a lot of parameters that your Centimeters can change about their oven to fine tune everything. Right? But with this particular solder, which was 95 5, it it required it required a a reflow standard that that didn't seem to fit nicely into either 1 of those.

Stephen Kraig:And so my in my opinion, I do think it is the contract manufacturer's responsibility to look at parts and to identify if there are any unique things about that. Now I don't III

Parker Dillmann:100% agree. What I was saying though is it's always nice to be nice to people, and if you it's it's 1 of those withholding information only hurts you as as a designer. Right? Correct.

Stephen Kraig:Yeah. Yeah. And I was just about to make the point. I think the best situation is you both tell them and they're responsible. Yes.

Stephen Kraig:I understand. In other words, like, yes, if there is something unique, flag that somehow. And and I think 1 of the solutions that we were talking about, and I think this is totally reasonable. What what what let's say there's 2 situations or solutions. What you just mentioned where you can add a part note in the Macrofab platform, that is probably by far the best way to do it, especially for Macrofab.

Stephen Kraig:But, you know, if there was if if if all you had was a fabrication drawing, perhaps a note on there saying, this this assembly includes parts with unique reflow, requirements and then call out the REFDEZ of that part.

Parker Dillmann:Yeah. I wouldn't that's fine. I would actually make the note on, like, the bill of material you're handling because you're handling this off to like a Centimeters that doesn't have a factory platform so and I know from past experience that a lot of CMs don't even read the assembly documents, so, putting that on your bill of materials is probably a better bet because they are going to have to

Stephen Kraig:read that. They have to read that. Yes.

Parker Dillmann:So putting that note there in, like, another cell at the end. Right?

Stephen Kraig:Yeah. Yeah. Yeah. Totally. Oh, yeah.

Stephen Kraig:Like, if there's just a cell that says notes or

Parker Dillmann:Yeah.

Stephen Kraig:Whatever. Put it in big bold. Yeah. It's it's fine putting it

Parker Dillmann:in the assembly dock. It's just I know from past experience with other CMs that a lot of times they don't read assembly docks. Right. Right. We've talked about that before on the podcast.

Stephen Kraig:The the the part about this that is difficult is so the responsible engineer for a board. Let's say that they're creating they design a board and they create a bill of materials for it. For the most part, the the design engineer is not an expert in manufacturing. They usually those they usually don't mix. And so it's not necessarily the design engineer's absolute responsibility to include that because it's not.

Stephen Kraig:They may not know that that is a an exact Yeah. Exactly. So that's why I still think it is the contract manufacturer because at the end of the day, it is their responsibility to provide a properly assembled device, but I totally agree with you. Like, it takes if you do know there is a unique thing, it takes a few extra seconds and it's just that much more in insurance to getting a properly assembled device. So

Parker Dillmann:now I kinda wanna build, like, a board that has, like, all these traps on it. Like, it has parts that you can't you parts that you can't water wash, parts that have weird reflow and like

Stephen Kraig:see how put them all on 1 board to make it as hard as possible

Parker Dillmann:that's hard as possible to make

Stephen Kraig:to make And and actually, you just mentioned it. That was the the next thing is is water washable. Is, so that is a note. Can can you assume that your Centimeters is going to scrub your bomb to look to see if parts were water washable or not? And and the answer is no and also yes.

Stephen Kraig:No as in similarly with the last situation, you should note that. If you know 1 of your parts is not water washable, you should absolutely flag that with your Centimeters. But so so they should be checking, but also put the note there. And I remember back at at, Maccab when I was working there, we did bomb scrubs for water wash or not. We we absolutely did do that.

Stephen Kraig:I remember doing plenty of that actually. And and the a lot of times, you can just look at a board and and know if it's water washable or not. Right? But you'd see a part where, like, I don't know. There's a part with a hole in the top of the of the the the package.

Stephen Kraig:You go

Parker Dillmann:Yeah. We need to do that. Relays that had vents. Yep. Or

Stephen Kraig:Microphones, MEMS stuff, pressure sensors, things of that sort.

Parker Dillmann:Yep. Oh, and you're talking about MEMS devices, a lot most of those can't be ultrasonic cleaned. Ultrasonic clean isn't really a thing for, I mean, it is still for PCBs, but it's much out of favor nowadays. It used to be a big thing in, like, the nineties, but once MEM components started kicking off the scene, ultrasonic cleaners just absolutely destroy the the mechanics inside of a of a MEM sensor. So

Stephen Kraig:Well well, so also my buddies over at NASA did a huge study on ultrasonic cleaning of electronic components, and they found that it, degraded capacitor terminal connections to the actual That makes sense. Of the capacitor. And so NASA has outlawed ultrasonic cleaning for any, electronic assembly. And so in a lot of ways, because of them, we just don't do it anymore. Even though that kinda sucks because ultrasonic cleaning is awesome.

Stephen Kraig:Yes. It's probably my favorite job.

Parker Dillmann:It's probably my favorite way to clean car parts. Yeah. I just put it in the cleaner and then I hit a button and then, like, 2 hours later, I walk by and I pull a clean part out.

Stephen Kraig:Oh, it's it's fantastic. Yeah.

Parker Dillmann:Yeah.

Stephen Kraig:That and, oh, gosh. My father and I, when we were working on bikes back in the day, he used to have a big jug of carb cleaner where you just take the carb apart, you put it in there, go to bed, wake up in the morning, pull it out, and it's perfect. Yeah. I I don't remember what it was called. It was like carb dip or something like that.

Stephen Kraig:Yeah.

Parker Dillmann:It's carb dip. It's made by companies. This was a b.

Stephen Kraig:That stuff was was amazing.

Parker Dillmann:Barium? No. It's not barium, but it's like DER Herb dip.

Stephen Kraig:Yeah. It's something like that. Didn't smell good and it looked like it had been cancer.

Parker Dillmann:Berryman Chem dip carburetor part cleaner.

Stephen Kraig:Yeah. Chem dip. That's what it was.

Parker Dillmann:It comes in a paint can. Yeah.

Stephen Kraig:It's a it's a paint can, but it has a little basket that goes in there. Yep. Yeah.

Parker Dillmann:If I if if I'm working on something that can actually a carburetor that actually could fit in there, I use that.

Stephen Kraig:Yeah. Your carbs are usually a lot way bigger than the 1 that I've picked on. Yeah. I love it.

Parker Dillmann:But ultimate, ultra cleaner does pretty good work on a on a carburetor. So

Stephen Kraig:Yeah. Oh, I this this was just a hair before I met you, Parker, but at my bachelor party, this is a total tangent here. But, at my bachelor party, we spent 3 days out of my buddy's land, which you went to, once or twice. But we went up there, and we we went to split logs on my buddy's old log splitter, and it wouldn't fire up. So we spent half a day cleaning a carb and drinking beer.

Stephen Kraig:And you know what? That was that was an amazing bachelor party. That was, like, just so much fun. And we totally got it working, you know. So I

Parker Dillmann:wanna do that right now.

Stephen Kraig:It wouldn't well, wait until it's cooler outside. Okay. Going into summer out out to the land out there was pretty rough.

Parker Dillmann:No. I'm just saying, like, drink beer and clean a carburetor.

Stephen Kraig:Oh, yeah.

Parker Dillmann:It's like it's like therapeutic. It is.

Stephen Kraig:Yeah. I I like I like getting my hands nasty and and grimy and dirty working on something out in the garage. And, you come in smelling like oil and and gas, and it just feels like you did something, felt like you worked. You know?

Parker Dillmann:Is it how I made this joke I think like last week to you, Steven, which is like, you know how hard you worked is how many shirts you went through.

Stephen Kraig:That's true. Yeah.

Parker Dillmann:So right now it's like 4 shirt days outside in Houston. So Oh, that's that's hot it is. Yeah. Anyways, back to, Yeah. So so so mind reading CMs.

Stephen Kraig:1 more bit of information that I think this 1 is a hot topic because I've I've seen engineers be way on both sides of the aisle.

Parker Dillmann:And this 1 this 1 ticks ticks my my anger anger a little bit. Panalyzing PCBs. Let your Centimeters do it.

Stephen Kraig:Yeah. I totally agree. I am in the same pay boat as you. I honestly I can see a reason why you would want to penalize your own PCB if you were designing, say, fixtures or something that made sense on your side where you wanted to receive boards in a panel and you depanalize them or or, like, say if you had, like, a programming jig where you could put, like, a whole batch in and do it all at once. But but for just standard boards, let your Centimeters penalize them.

Stephen Kraig:It usually makes their life way better. And and frankly, in my experience, they're way better at penalizing than you are.

Parker Dillmann:Like And it's gonna be cheaper for you. Yeah. Yeah. Typically. Yeah.

Parker Dillmann:Because the CEM is not going to penalize them in a way that costs more money. Now I agree if you have pre existing tooling this is the thing though you can tell your Centimeters be like hey, I have pre existing tooling and here's my board outline and border locations and soldiers let them penalize it. It saves you a bunch of work.

Stephen Kraig:Yeah. A ton of work. Yeah. Yeah. And, and on top of that, like, the way penalizing works in every EDA tool is different, and you can get wildly different results and, you know, knowing how to do v scores or or mouse bites, properly, your Centimeters is gonna know what works for their machines.

Parker Dillmann:Yep. What machines they've got. Do they have a pizza cutter style v score machine, or is it a do they have a fancy laser cutter? Who knows? Right.

Parker Dillmann:I mean, you can

Stephen Kraig:ask them And and and I've seen I've I've seen people penalize stuff in really awkward ways where, you know, they'll do, like, a 1 by 8 array. So it's this big long line of boards, and then maybe that's too long for the machine, and they can't build the first or the last board on that array. And if you just done, like, a 4 by 4, or I'm sorry, AAA 2 by 4 array, then they could have gone on done all 8. And and so, like you were saying, that it can it can it can bite you in the butt if you do it. Now I think you can work with your Centimeters, That's another option.

Stephen Kraig:Like, they can tell you the the the parameters and you can if you still have to be the 1 who panelizes things, maybe you can work together to do that. At the at the same time, I've I've run into this in the past. You can work with your Centimeters, to panelize to a particular number per panel. Like, let's say, you wanted or or let's say your Centimeters was, like, hey. I wanna do a 2 by 2 array.

Stephen Kraig:Well, then you know it makes sense for you to purchase in multiples of 4. So so don't don't buy 3 boards when they're panelizing on a 2 by 2 array. Right? Because then you're just throwing away PCB real estate. So this really ends up being a conversation with your Centimeters and but but for the for the most part, I absolutely agree with you, Parker.

Stephen Kraig:Let your Centimeters do it. You could just give them the Gerbers, and they'll handle the rest. Yep. Because even you can get into, like,

Parker Dillmann:copper thieving and stuff like that that happens on the, fabrication side for the board when it gets penalized up. So Mhmm. Making sure it works in their process.

Stephen Kraig:Also, remember, your board doesn't necessarily go through 1 machine. It goes through multiple. So it had it goes through paste, it goes through reflow, it goes through your pick and place, and it might also go through, some kind of through hole processing at the same time. So your Centimeters is gonna know the requirements for all of those machines. You may know the requirement for only 1 of them.

Stephen Kraig:So it just makes way more sense for your Centimeters to handle that. And I think that is out of all of the things in this list that we've talked about. So the reflow profile, the soldering of unique, BGA packages, parts washing, and panelizing, I think this is the 1 thing that you can absolutely rely on your Centimeters to do. All of the others, it makes sense to help guide them with extra information. This is the 1 where you can be, like, here's my Gerbers, penalize them in the way that makes the most sense for your manufacturing line.

Parker Dillmann:Yeah. Again, the only gotcha is if you have pre existing fixtures. But the best way to handle that is be like, hey, here's my preexisting fixture, and this is how it's designed. And then they can make a panel that fits that and also fits their processes. Right.

Parker Dillmann:Right. Like how big the rails is? How big is the spacing between anything that like, little locating pins? Where does the panel fiducials go? Right.

Parker Dillmann:Right. Yes.

Stephen Kraig:In fact, I've ran into it once where, we had somebody penalized something and the rails were they would be accepted by our machine, but the laser that senses the board as it comes into the machine was just over a particular cut out. So, all of the boards would be sensed at the wrong location when they came into the machine, and that was a situation that we wouldn't have run into if we had done the panelizing our self. So that you know, did were the boards able to be made? Yes. But we had to do extra work to get around that.

Parker Dillmann:Someone had to stick their finger in there.

Stephen Kraig:Yeah. Yeah. Stop now. So it's little it's just little things like that. I mean, we we literally had to readjust our laser sensor on our machine because of 1 customer's panelization that they did.

Stephen Kraig:And they did a totally okay job panelizing it. It just didn't function great with our machine. Mhmm. So I don't know. Hopefully, that's some extra information.

Stephen Kraig:The the the general rule of thumb is give your Centimeters information, but you can trust them.

Parker Dillmann:Yep. And if you disagree, fight us atform.macafab.com.

Stephen Kraig:I like everything is fight us. Alright.

Parker Dillmann:Go for it. Go ahead. Oh. Well,

Stephen Kraig:I was gonna say let's move on to personal projects.

Parker Dillmann:Yeah. Yeah. Yeah. Props fan. Project I've been working on for a long time and threw away because the, the use case went away, I guess.

Parker Dillmann:But now it's back. So what prop fan was was an automotive controller for a fan that you know the temperature sensing PWM control all that good stuff, and it used the parallax propeller. This is a long time ago. Oh, yeah. And, this is like start of the podcast era.

Parker Dillmann:And I've restarted the project a couple times, but now I am fully on building this. I got like most of the schematic done over the last

Stephen Kraig:weekend. Well, I I do have a question for you real quick. So you said this uses a parallax propeller.

Parker Dillmann:Does not have

Stephen Kraig:this anymore. Oh, does not. Well, okay. But well, that Before it did. Yes.

Stephen Kraig:Before it did, it does not now, but you had bought a prop 2. I did buy a prop 2.

Parker Dillmann:It wasn't for this project though.

Stephen Kraig:Have you turned it on?

Parker Dillmann:Yeah. I turned it on.

Stephen Kraig:Oh, okay. So you so you've played around with it? Yeah. Yeah. I turned on when

Parker Dillmann:I first got it.

Stephen Kraig:Okay. Yes.

Parker Dillmann:Years ago at this point. Yeah.

Stephen Kraig:Yeah. Yeah.

Parker Dillmann:Yeah. And so, this is so there's a an automotive fans for electric fans that cool down your your radiator. For the past, I want to say 6 or 7 years now, almost every single OEM out there has moved towards brushless fans. Mhmm. Because it simplifies a lot of the control schemes because now you you basically move your drivers into the fan housing into like the motor housing and they got heat sinks so so you actually keep the motor driver like the MOSFETs cool.

Parker Dillmann:And It also supplies everything on the other end where like now you just have to supply it power in a PWM signal, right? So you don't have to you have to have like a big MOSFET driver like you know actually pulsing a DC motor and everyone's been moving towards us you can actually get these fans like almost every single vehicle has them now and, so they're easy to get, you can go to like AutoZone and you can buy these fans, and these aren't like your old school, like, dinky little fans that they would put on, like, hot rods and stuff back in the day. No. These are 800 watt brushless fans that are pulling like 3, 500 CFM after it's gone through a radiator. So that's like with its, what do they call that?

Parker Dillmann:The static pressure. So they have a insane static pressure where they can just draw through these fans, and they're designed to be run all the time. They're like a 100% duty cycle fans. These are like insanely overbuilt fans. They're just beefy.

Parker Dillmann:Yeah. Beefy fans, And they range from I think you can go down to like 450 watts up to like 875. 175 watts is like the range you can get these things in

Stephen Kraig:also they're intended to run at like what's the temperature of an engine bay

Parker Dillmann:200 degrees. Yeah. Yeah.

Stephen Kraig:So so yeah. There's they're meant to be run hot and put away wet.

Parker Dillmann:Yeah. Yeah. Exactly. So I I've I've been working with I have 2 of these fans I've been working with, just so I can get around or just start playing with the ones a 500 watt, ones an 850 watt motor. Because they have both different all these use different PWM schemes.

Parker Dillmann:They all center around like a 100 Hertz for the PWM, but the different scaling of like what the actual pulse width is. Some companies like to do like a normal like 10% pulse width is 10% fan speed. Something like have a linear scale, some are like the exact opposite Jeep is that way Jeep likes to be like 80% is low speed and it ramps down kind of weird. So if you get 1 of these you have to play with like what is it scaling, for the ramp. So basically I'm designing a controller for this.

Parker Dillmann:There's a couple people that do this out there, but I want to build an open source 1 that also has some extra features. And we'll get into the extra features later, though. So the first the first part of the puzzle is how do you power this thing? But the the fan is easy. You connect it to 12 volts.

Parker Dillmann:Right? Boom. Done. You can't it's actually like an 8 gauge wire too because it's if you think like 800 watts at 12 volts, you're at like 70 something amps. And so yeah you need an 8 gauge wire, and it's actually like that's like the max size all these they all use the same connector too.

Parker Dillmann:We talked about this before but they all use the same kind of connector. I wish I remember what the part number was for that connector. I'll have to post it because it did take a while to find what like the computer side of that connector is, but the max size of wire you can fit in there is an 8 gauge like TXL style automotive jacketed wire. But, to actually power the the controller, long long long time ago, I found a, white paper from analog actually it was from, I think it was from Maxim before they got bought out. No.

Parker Dillmann:It's by Linear Tech. That's right. It was before, it was a white paper by Linear Tech before they got bought by analog. K. And so like if you open up the PDF that's in this URL it has all like linear tech colors.

Stephen Kraig:Yep. Yep. Yeah. Classic.

Parker Dillmann:Yeah. So they use an lt8672 for circuit protection and that's a basically an ideal diode controller, which is a fancy word for a MOSFET controller. Right. With reverse current protection so it's got like sensing circuits so it can see if it's reverse biased. It can clamp on transient voltages and that kind of stuff.

Parker Dillmann:I would if if anyone's interested in doing any kind of like automotive devices, at least check out this white paper because it has a lot of, like, edge cases that happen in automotive. Like, what happens if the battery gets disconnected? Because that the battery is, like, what's used to regulate a lot of these systems, and you take away the regulation parts. Mhmm. And then you have this like, alternator just goes going crazy with its output right and spiking all over the place because it doesn't have anything to level out its output.

Parker Dillmann:Anyways go check this out. We'll put a link in the show notes, but what I'm using also for is to control, the actual powering of the rest of the circuit. You don't wanna leave this thing connected to battery all the time. You want it to turn off when you turn the switch off. And so I'm actually going to use the enable pin on this chip.

Parker Dillmann:So when you put your key in, and then turn on the key, we call that, like, ignition voltage or switched voltage. So the switch voltage will go into the enable pin and when enable goes high it will actually open up that ideal diode in quotes and allow So

Stephen Kraig:it's it's a load switch.

Parker Dillmann:Yeah. Yeah. It's a load switch. Yeah. But it's also I'm able to dual purpose it basically.

Parker Dillmann:Yeah and of course like that's 12 volt switch you also have to make sure you're not gonna blow it up so it has like TVS protection and all that good stuff. And then the next thing I wanted to make sure to do was, I want to be able to see like the temperature that the fan controller is seen. Because a lot of fan controllers that people like for auto at the market, it's just a box that sits under the hood. So you don't actually really know what it's doing. You just hope it's doing what it should be doing and, it's reading the temperature correctly and it's turning on at the right time.

Parker Dillmann:I've been burned by so many of these aftermarket controllers that I'm like, no. I want to know if my controller thinks it should be on or thinks it should be off and what temperature it's reading. So I wanna know this information. So I'm like, okay. I need a screen that tells me this information.

Parker Dillmann:And so I'm gonna go with a crystal fonts cfa533 TFHKC so this is a 16 by 2 character display that's automotive spec'd but it also has a like, buttons pad on it. So you can go through menus or you can set temperatures or stuff like that. You can set all that stuff there, and it talks I square c.

Stephen Kraig:So there's a problem. That's con that's convenient.

Parker Dillmann:Well, it's convenient, but this thing is inside the cab. My PDM controller is under the hood. Sounds like you need to go differential signal. Yes. Because I'm going to use a PCA 9615, which is an I square c to differential signal converter.

Parker Dillmann:And I actually use these in the past and these work great. So what that does is basically takes your your clock and your data signal and converts it to a differential signal over 2 twisted pairs. You run that through Ethernet, and then it goes on to the other side, and you have another 1 of these PCA 96 fifteens, and it converts it back to I square c.

Stephen Kraig:What do you know what protocol it's talking over?

Parker Dillmann:On the actual, differential signal? Yeah. Don't know, don't care. You did that. Like, you

Stephen Kraig:just buy 2 of them, plug them together.

Parker Dillmann:And it works and it works great. Yeah. It's like, we were experimenting them for DEF CON projects and they work great.

Stephen Kraig:Now you got me raising an eyebrow. What are you using? What are you needing to send over long cables?

Parker Dillmann:Uh-huh. Maybe I'll

Stephen Kraig:you'll have to kill me. Yeah. Yeah. It'd be cool. That that was a

Parker Dillmann:couple years ago we were experimenting with it.

Stephen Kraig:Oh, okay. Cool.

Parker Dillmann:Yeah. Nothing current right now, I don't think.

Stephen Kraig:Gotcha.

Parker Dillmann:So I'll have an ethernet cable between the 2, makes it super easy to wire up because you could pass power, for the screen and ground, but then I got to thinking, I'm like, oh, what if I put a USB port on my display? So I can plug if so I don't even have to go under the hood to actually, like, let's say, oh, I want to look at the serial terminal, the COM port on my my PWM controller. Well, now I can just hook it up into the display.

Stephen Kraig:That's cool.

Parker Dillmann:Yeah. And I just well, I'm like, oh, I need a flash of firmware instead of having, like, go under the hood and open up the box and because I'm gonna use a waterproof enclosure. Instead of having to do all that I can just plug into the

Stephen Kraig:Right into the display. That's cool.

Parker Dillmann:Yeah. So the big feature I want that no 1 else does for these kind of fans is I want to read how much current the fan is pulling. Mhmm. And I'm gonna use, like, an Allegro, you know, pass through chip to do that. Mhmm.

Parker Dillmann:And this is the reason why, is sometimes it's the controller that fails, sometimes it's the fan that fails, sometimes it's, you know, something else. Right? Like a relay gets stuck or or fails to close or something like that. K. So what I wanna know is like, hey, if the fan's on, I should be pulling some current.

Parker Dillmann:Right? This 850 watt fan depending on what speed it is. Right?

Stephen Kraig:But but any speed should be a a fairly significant

Parker Dillmann:Should be something. So I actually wanna plot that, like, at I if I'm, like, not moving, how much current am I pulling? Like, at different ranges. And that's 1 of the things I wanna do is, like, can you detect how fast your car is going? Like how much air is moving through your radiator?

Parker Dillmann:Can you detect like if you're commanding let's say 80% fan speed and you're driving 60 miles an hour, can you actually detect that on the load?

Stephen Kraig:I don't know if you could do that reliably. You'd have to take a lot of data to be able to plot all of this and then figure

Parker Dillmann:it all out. But the thing is I wanna be able to do that.

Stephen Kraig:So I

Parker Dillmann:want I wanna experiment with this. That's actually another thing is, like, I wanna have speed control because some, some applications are like, oh, if you go above 45 miles an hour or whatever, you wanna make sure you're not running the fan at all. Because some, some car packaging, you don't want to run the fan because the fan inhibits flow when it's running. Right. And so you need to be able to test speed.

Parker Dillmann:And so you I'll be able to need I need a way to, like, detect, like a speedometer signal, which is like a spike pulse at 12 volts. But what I also want to be able to do is I want to experiment with GPS control. GPS speed control, and, I've been playing around with that a bit night. I I need to work more on it because I can't get fast locks. Like, it needs to be able to, like, lock on within, like, ideally within maybe 30 seconds of the key turning on.

Stephen Kraig:And

Parker Dillmann:I haven't figured that part out yet. So if anyone out there knows, like, a cheap GPS units that can be under the hood of a car, now you have like metal on top of it which sucks for GPS but to be able to like sense the speed because that's all it needs. It doesn't need location. It just needs to have, like, real it has to have, absolute speed. Doesn't it doesn't even need velocity.

Parker Dillmann:I just need to know how fast it is moving. Sure. Yeah. And then I want to do like multiple temperature inputs possible, be able to control off based off your your AC compressors on or off stuff like that. So I was looking and I have all these like analog inputs, analog outputs, I have digital inputs, digital outputs, and I'm like okay, I need to be able to protect these low level stuff.

Parker Dillmann:And so, I came over some ideas for that, but I was like you know what? There's a couple open source like engine managements hardware out there called Speeduino and Megasquirt, and it was like, I wonder how they do it. That was way over complicating my circuitry. So I'll post the schematics I found online, the the open source schematics for these these 2 devices. But like for like analog sensor inputs, you know, you have an analog in pin and what they do is they first pull up the pin because most sensors only, can pull down.

Parker Dillmann:Right. And then it goes you basically have a low pass pi filter. You have like a 1 nanofarad, and then it goes to like a big chunky resistor, and then you have a 1 microfarad on the back end of that, and that goes into your analog in pin. And that's enough. Some some circuits actually put a TVS diode there on the, like, right at the connector.

Parker Dillmann:I'm gonna do that, but most don't do that even do that. Like Yeah.

Stephen Kraig:That 2 point They just rely on the filter doing just Yeah.

Parker Dillmann:The filter does it good enough job at it. Sure. Yeah. And then there's like chips like the SP 72 1, which is a SCR which is a silicon controlled rectifier, TVS diode array which has like semi active suppression of transient voltages. It's kind of cool stuff.

Stephen Kraig:I have not heard of that.

Parker Dillmann:Yeah. I've seen that used in in some of these motor controllers or engine controllers I should say, so I would use those. That seems to be like enter like industry standard for automotive design. So why make a new standard? Just copy it.

Parker Dillmann:Right? But I'm really interested in the current jaw. I want I want to really see, like, even if I'm not even, like, detecting how fast I'm absolutely going, like, can I detect that my fan shouldn't even be on? Right? Because, like, I'm combining, like, the engine's running super hot, and so the fan is running really hard and but I'm, like, not pulling that much currents.

Parker Dillmann:That might be, like, a situation be, like, hey, something's, like, weird. Right? You should probably, like, pull over and figure out what's going on. Like, something's not working correctly. They're, like, it could be, like, hey, I'm commanding the fan to run and not pulling any currents.

Parker Dillmann:Like, so something's up with the fan or, like, the current fan's pulling way more power than it should. Like, I wanna know these edge cases so then I don't end up, like, you know, blowing up a motor.

Stephen Kraig:What what what's 1 of your cars? I mean, I know you're making this generic, but which 1 of your cars are you wanting to put this in? This is gonna go in the red jeep. So you okay. Is it possible is there any, actually, I don't know this about cars.

Stephen Kraig:Do cars report what gear they're in electrically?

Parker Dillmann:Modern cars, yes. The red jeep, no. Because I was about

Stephen Kraig:to say, you could just take the gear and correlate it to an RPM and then that would give you a speed.

Parker Dillmann:You can just read your speedometer. So most most cars, your your speedometer signal comes off, like, the tail end of your your, transmission. Actually, even newer cars that just goes through the transmission controller. It just has an internal sensor on the output. Anyways, you can just read that square wave and

Stephen Kraig:And that's good enough. And that's good enough.

Parker Dillmann:I mean that's how the car knows how fast it's going. So It's good enough for

Stephen Kraig:the car. Yeah.

Parker Dillmann:And so to be able to hook up that sensor, because I thought about using, like, 1 of those, like, donut rings for the current, and I'm like, nah. I wanna use, like, an onboard sensor. It's more way more accurate too. So I need to be able to hook big chunky wires up to the board. I didn't really want to do like screw terminals, like a big screw terminal because, those kinda tend to vibrate loose and that kind of stuff, and I'm like, you know what?

Parker Dillmann:I want to do, like, battery like like a like a crimped lug on the end of the cable, And so I need to put that on the board, and I didn't really want to do, like, a contact and, like, pass a bolt through and then have to, like, have a nut on the backs of the PCB. So I found like s and t style threaded inserts are a thing like Keystone makes them. There's a couple other manufacturers up there too, but they none none of them make 1 that's big enough to handle an 8 gauge wire, and so I found a company called Lugs Direct And the moment I found, like I think Steven and I were talking 1 night, and I found this website. I just couldn't get over the fact that it's just Lugs Direct. I love the name.

Stephen Kraig:They do 1 thing. Well, I mean, they do a lot, but clearly, they do Lugs. Lugs. And

Parker Dillmann:and they have a lot of different styles like SMT and through hole threaded inserts that you can connect big wires up to, and so I found some that work. I'm gonna go through hole because it makes sense for this part And then the howls the entire thing. So, like, the part that's inside the cab doesn't really matter. It's gonna stay dry. I'll probably just make like a 3 d printed enclosure for it.

Parker Dillmann:But for under the hood it needs to be waterproof and needs to handle heat. It needs to also help reject heat if possible. There's not a lot that's going to be going on inside this box, but you know it's gonna get heated up.

Stephen Kraig:Oh, for sure. So I want to

Parker Dillmann:go with an aluminum enclosure and I think I'm gonna go with what's called an EX52 by Polycase because it's a waterproof extruded aluminum enclosure So I can actually take the end plates off, I can machine the end plates with the ports I need, and then install the right waterproofing connectors on the ends of it, and then I can assemble the unit and install it. Right.

Stephen Kraig:And doesn't it have, the the internals of the case has places for you to slide a PCB into it?

Parker Dillmann:Yes. Yeah. So you can slide a PCB, like, in the middle of it. Right.

Stephen Kraig:Right. That's convenient.

Parker Dillmann:Yeah. And so the the PCB will just just fit snugly inside and be good to go.

Stephen Kraig:Oh, also, it has it has some mounting flanges.

Parker Dillmann:Yes. That was that was the big thing is finding a waterproof extruded aluminum enclosure that had mounting flanges.

Stephen Kraig:Yeah. These are convenient. Yep. So Also, it's not expensive and neither are the flanges, or not too expensive, I should say.

Parker Dillmann:Yep. Yeah. I was actually pretty happy with it. Nice. So I haven't ordered it yet but the specs make me happy.

Parker Dillmann:I'm gonna wait till I order I'm gonna order the board first before I order the enclosure. So what's left to do on the board is I need to finish up some of the circuitry on the schematic and then do the routing. And then I have to design the board that goes in the back of the display that goes in the cab. That's it. Nice.

Parker Dillmann:Feels like I'm over halfway done. I got I got all the hard stuff, I think, done and everything feels like it's gonna work. Like, the the the the theory of operation seems to like, I have all the right parts, And they're all connected in the right order. Right.

Stephen Kraig:Now you just need to execute on it.

Parker Dillmann:It's only most I'd say over halfway executed too.

Stephen Kraig:So Well, I mean executed as in, like, you gotta have it in your hands and you actually have to, like, turn a fan. Turn a fan. Yeah.

Parker Dillmann:Yeah. Yeah. A 100%. Because I've made, like, my Sam d 21, dev board. I made it turn I've turned this fan.

Stephen Kraig:So Yeah.

Parker Dillmann:It it works. Now it's all the other stuff it has to do and and pay attention to. Yeah.

Stephen Kraig:And care about it. Yeah.

Parker Dillmann:And so I am gonna make it open source, so people can iterate on it and add, like, oh, I want to be able to control 2 fans cool put another PWM you know protection circuit and run out of the case. Mhmm. So I I wanna make it I should have there should be plenty of board real estate on the on this enclosure, or allowed by the enclosure, I should say, so that people can easily add, like, another whatever into it.

Stephen Kraig:Well, there's not a huge amount of things going on. So No. I think, yeah, I think you should be able to do that fairly easily.

Parker Dillmann:Yeah. Yeah. It might get complicated inside if we add, like, a GPS unit, an optional GPS to read speed. That might be the more complicated thing, like how do you get the GPS antenna in there? Or like is there a way you don't need a really good lock with GPS just to get speed readings?

Parker Dillmann:Because I know they make GPS basically speedometers for old jeeps and old vehicles. So you don't need like the old speedometer cable anymore. It's like how does that thing get a lock so fast? I don't know. I've experimented with, like, a cheap GPS unit on my desk and, like, it takes like 5 minutes for it to lock on.

Parker Dillmann:I'm like that's not really acceptable.

Stephen Kraig:Right. That doesn't help you very much at all.

Parker Dillmann:No. So Well, cool. It's fun to

Stephen Kraig:see an old project come back to life.

Parker Dillmann:Yeah. And this 1II need. Because I because I what what happened is on the red Jeep, I burnt up my last aftermarket controller, and I'm just like fuck this shit. I'm building it my

Stephen Kraig:own now.

Parker Dillmann:I'm done buying off shelf ones, and I'm like I am going to build 1 and use 1 of these badass OEM fans that is designed for what I need it for now.

Stephen Kraig:Well, now you can just burn up your own controller.

Parker Dillmann:Well, the great thing is, like, it doesn't actually have. It shouldn't burn up at all because it doesn't have any control circuitry besides the signal. Right. Right. The the Jeep has really weird aerodynamic problems that mean that you have to run a fan a lot.

Stephen Kraig:Challenges. Don't you say problems?

Parker Dillmann:Yeah. It has challenges with aerodynamics. It's really hard to force air into the radiator. I'll put it that way. It's interesting as modern jeeps also still have the same problem.

Parker Dillmann:I think it's the problem with just having a lifted vehicle is you get a lot of high air pressure under the vehicle, which is not good for airflow for your for your fan. I mean, they got there. Getting or just getting air through your radiator because most time you have a low pressure zone underneath your car. Yeah. And so your car has a high pressure where the radiator is

Stephen Kraig:at. But it wants to

Parker Dillmann:drink air. And it wants to drink air and it will then that hot air goes under your car. Right. That is not a thing on a Jeep.

Stephen Kraig:Also, the original designers, III think they they used bricks as their, inspiration for for designing the car. So I don't know like these kinds of things didn't seem to be forefront in their mind when originally designing these these jeeps. They they had they had other criteria they were looking at.

Parker Dillmann:Yeah. Other criteria. Yeah. And so, like, if you look at modern jeeps that are using these 850 watt fans Yeah. They're running them they're not running them a 100% through, it's like a 100% of time, but they're running them on the freeway at, like, 40%.

Parker Dillmann:So they're actually running them. Mhmm. So I'm, like, good. So and there's no widespread problems with these at all, like, everyone's just like, yeah. It's like, honestly, the most reliable jeeps because they're not overheating all the time.

Parker Dillmann:Because they have now a fan that's able to it. I'm like good. I'm gonna retrofit that into mine and make that work. So and the great thing is like it's an OEM fan and so you only have to pay you you can pay OEM and aftermarket prices. You don't have to go buy a specialty fan now.

Parker Dillmann:So it's like a quarter of the cost. Yeah. So I'm look I'm looking forward to it. Like, people need to be at least in the automotive world need to like, for hot rods need to really start looking at these fans. And I'm hoping to provide a controller that, like, enables people to use these fans because they're awesome.

Parker Dillmann:They levitate.

Stephen Kraig:They'll they'll float around on their own?

Parker Dillmann:They'll float around and hover.

Stephen Kraig:Yeah. Wow.

Parker Dillmann:It's how much power how much They're just beefy. Well, yeah. Because you have 850 watts of motor and they're thick because they, because it's a it's a brushless motor and how they can design it so they can inset the motor more into the hub. Mhmm. And so they can have basically steeper blades.

Parker Dillmann:Pitch angle? Pitch angle, and they have more torque than a standard brushed motor. And so you can really get the air moving that static pressure up. Right. So looking forward to it.

Parker Dillmann:I'm I'm gonna try to work on this over the, 4th July break. That's my goal. Just work on it. So maybe I might not get to, like, fully routed by then, but I'm hoping to get, like, schematic done, parts put on the right spot on the board, like, have a border outline that I know will fit in the enclosure That's it. Alright.

Parker Dillmann:And if you wanna talk about this controller, hit us up at form.macfed.com. Let me know how what feature you want it, like, if I didn't mention a feature or, like, the GPS. I really wanna know about the GPS because I'd love to have that as a thing you can do if you need that functionality. Yeah. Ideally, you shouldn't need it because if you start moving fast enough more air comes in and it cools down the temperature and then the temperature sensor goes, okay, I can turn off the fan.

Parker Dillmann:That usually how it works, but sometimes you have edge cases where like like, in my case, aerodynamic problems. But some people might have packaging problems where, like, there's a engine right behind the fan, so there's not a lot of airflow to begin with. So, like, when the fan the fan doesn't know to turn off because it doesn't hit that, like, tripping point to turn off when it's driving down the freeway. There's a lot of edge cases, so having speed control is a good thing. Right.

Parker Dillmann:Yeah. Let us know. Form.macrofab.com. And thank you for listening to circuit break.

Stephen Kraig:We were your hosts, Stephen Craig And Parker Dohlman. Take it easy.

Parker Dillmann:Do you wanna do the outro this time?

Stephen Kraig:Thank you, yes, you breaker for downloading our podcast. Tell your friends and coworkers about the circuit break podcast from Macrofab. If you have a cool idea, project, or topic you want us to discuss, let Parker and I and the community of Breakers know. Our community where you can find personal projects, discussions about the podcast, and engineering topics and news is located atforum.macrofab.com.